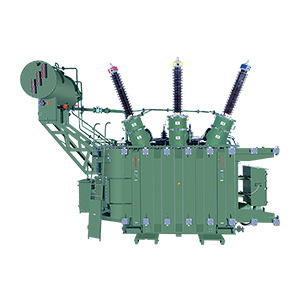

Features Of On Load Distribution Transformer

Electric Circuit is made using electrolytic grade with 99.99% pure High-Quality Copper from our regular and reputed vendor HINDALCO & STERLITE with Foil winding in L.V coil of transformer.

Magnetic Circuit is made using step-lap design for lower losses and low magnetizing current of core by using high quality CRGO material with grades such as ZDKH, ZDMH, AMORPHOUS, MOH, etc.

High Dielectric Insulation property to withstand lightening impulse and voltage surges.

ONAN through natural convection for effective cooling through axial and radial ducts.

Benefits of On Load Distribution Transformer

Due to on load tap changer, the voltage at LV side remains in limit against the voltage fluctuation from HV side.

For changing tap, shut down of factory is not reliable. But due to on load transformer you can or RTCC change the tap even when your factory is in full load.

As there is RTCC panel with AVR (Automatic Voltage Regulator), LV side voltage remains in desire range by changing tap automatically.

Due to on load transformer increase industrial machinery life’s, low maintenance & low power conception.

Onload Transformers are installed where voltage fluctuations from HV side are continuous. So onload transformer changes tap using AVR without any power-cut and give constant output voltage. Thus, over-all power consumption of industry gets optimized hence results in power savings.

| Type |

Indoor/ Outdoor Pad Mounted |

| Voltage Class |

11, 22, 33 kV |

| Vector Group |

Dyn11 |

| No. of phase |

3 phases |

| Frequency |

50/60 Hz |

| Tap Range |

+5% To -15% in 1.25% steps in 17 position or +5% To -15% in2.5% steps in 9 Positions or as per requirement of customer. |

| Winding Material |

Copper/ AluminiumFoil. |

| Applicable Standards |

BIS-1180 |

| Painting |

Epoxy, Polyurethane or specified by customer |