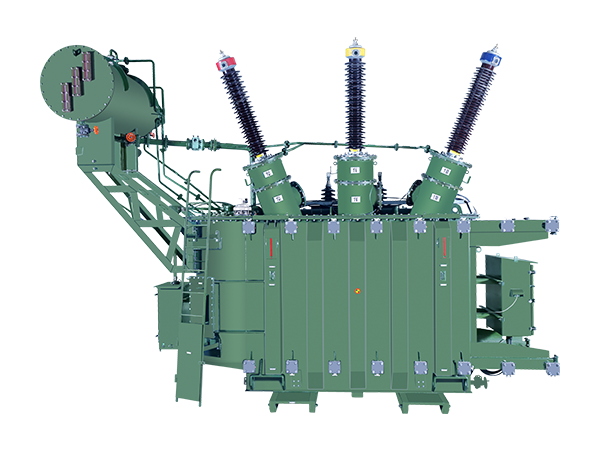

Power transformers are designed to be used for step-up and step down the application in the transmission network of higher voltages like 400 kV, 200 kV, 110 kV, 66 kV, 33kV, etc. The transformers are generally rated 200MVA and above. The designing make the transformers 100% efficient in transmitting heavy load and high voltage i.e., higher than 33 KV. If compared to the size of the distribution transformers, these transformers are bigger and are used in transmission substation, generating station and application areas requiring high insulation level.

We produce power electrical transformers of capacity up to 50 MVA, 3 Phase, up to 132 KV Class, ONAN/ONAF/OFAF/OFWF Cooling. Our transformers are popular for its trouble-free long performance, reliability and very competitive prices.